By Jane Marsh

Guest Writer for Wake Up World

If you think of solar panels as heavy, fragile and unwieldy, you’re not alone. Modern photovoltaic panels can weigh more than a border collie — and they’re much less cooperative. They’re also inflexible and cased in glass, making them one job site accident away from shattering.

[pro_ad_display_adzone id=”110028″]

However, thanks to advances in manufacturing, engineers may have found a solution that makes solar panels light and bendable. Enter injection molding.

What Is Injection Molding?

Before you can understand how injection molding could revolutionize solar energy, it’s important to clarify how the process works and what it’s used for. Injection molding is a manufacturing technique where a technician loads a bunch of plastic pellets — also called polymer granules, with an appearance similar to aquarium gravel — into an injection molding machine.

The machine heats the granules until they melt. Then, it injects the hot, liquid plastic into a mold. The plastic cools down and hardens inside the mold to form its final shape. Once the plastic part solidifies, the machine ejects it.

This process can produce thousands of identical plastic pieces in a short time. It’s extremely cheap and much faster than 3D printing or computer numerical control (CNC) machining. Injection molding is useful for making everything from bottle caps and toys to plastic furniture. It also has several applications in manufacturing car parts and hand tools.

How Can Injection Molding Help Produce Solar Panels?

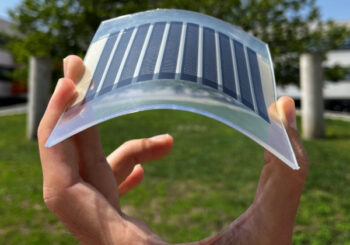

Engineers have discovered they can embed solar cells directly into plastic using an injection molding machine, creating thin, bendable solar modules.

For example, engineers at the MADRAS project — a European Union-backed effort to improve electronic manufacturing — have been printing solar cells onto thin plastic sheets. They then use injection molding and laser cutting to attach them to plastic parts. The result is a lightweight yet durable solar cell that performs well even if you bend it.

This type of thin solar cell becomes even stronger when engineers attach it to fabric. Engineers from MIT have created solar cells thinner than a human hair that generate 18 times more power per kilogram than conventional solar panels.

Since the solar cells are so fragile on their own, the MIT team began laminating them onto Dyneema, a strong composite fabric weighing just 13 grams per square meter. They used UV-curable glue to attach the solar cells to the fabric.

One tradeoff for durability is that the Dyneema-backed solar panels don’t generate as much energy — about 370 watts per kilogram versus 730 watts freestanding. Still, the flexible solar fabric has countless potential uses in many different fields. The team is now looking for ways to encase it in flexible packaging that would protect it from the elements.

Applications for Flexible Solar Panels

Flexible solar panels already exist in a limited capacity. However, they’re still expensive and not as efficient as their traditional counterparts. Inexpensive, injection-molded solar panels glued to fabric would do more than just promote the use of renewable energy — they would allow us to integrate solar power into our daily lives.

[pro_ad_display_adzone id=”110030″]

Imagine boat sails that could harness the energy of the wind and sun, reducing the need for fossil fuels. Solar cells could power tents during emergencies, heat food and water in remote areas and provide shade in the form of flexible canopies at parks. Solar clothing could keep rescue workers warm in a snowstorm or cool them off on a hot day. It would be easy to roll up and transport fabric-backed solar cells.

Flexible solar panels could also be installed on rooftops that couldn’t support full-sized solar panels. They could turn windows into transparent power generators. Additionally, they’re light enough that they could be placed onto drone wings, powering the vehicles for hours without the need for heavy batteries. The whole world could go solar.

The Benefits of Injection-Molded Solar Cells

Because injection molding is such a cheap process once you’ve created a reusable mold, it could make solar cells much more affordable than they are today. Solar cells would become widely available — perhaps you could even buy them at your local hardware store.

Installing flexible solar cells would probably be a breeze, as they’d be much lighter and easier to manipulate than the traditional 40-pound solar panels found on modern rooftops. Flexible cells are as thin as a piece of paper. Meanwhile, a typical solar panel is the weight of a bag of dog food, often requiring multiple people to carry it onto the roof and install it. Going solar would become much more accessible for many people.

New Horizons

Injection-molded solar cells have the potential to revolutionize our world. They could provide accessible energy in the form of sunlight, reducing our reliance on the fossil fuels — coal, oil and natural gas — that pollute the environment and contribute to climate change.

It’s only a matter of time before flexible solar panels become part of everyday life. Thanks to injection molding, the future of solar energy is looking bright.

About the author:

Jane is the founder and editor-in-chief of Environment.co where she shares practical tips on how to live a greener life.

Jane is the founder and editor-in-chief of Environment.co where she shares practical tips on how to live a greener life.

[pro_ad_display_adzone id=”110027″]